-

NEUIGKEITEN

- ERKUNDEN

-

Themenwelten

-

Gruppen

-

Aktivitäten

-

Artikel, Erfahrungen & Tipps

-

Mitsegel-Börse

-

Fragen & Diskussionen

- Seemannschaft

-

Sicherheitseinweisung

- Lernen

-

SKS - Prüfungsfragen

- Sonstiges

-

Karten-Ansichten

-

Dokumente

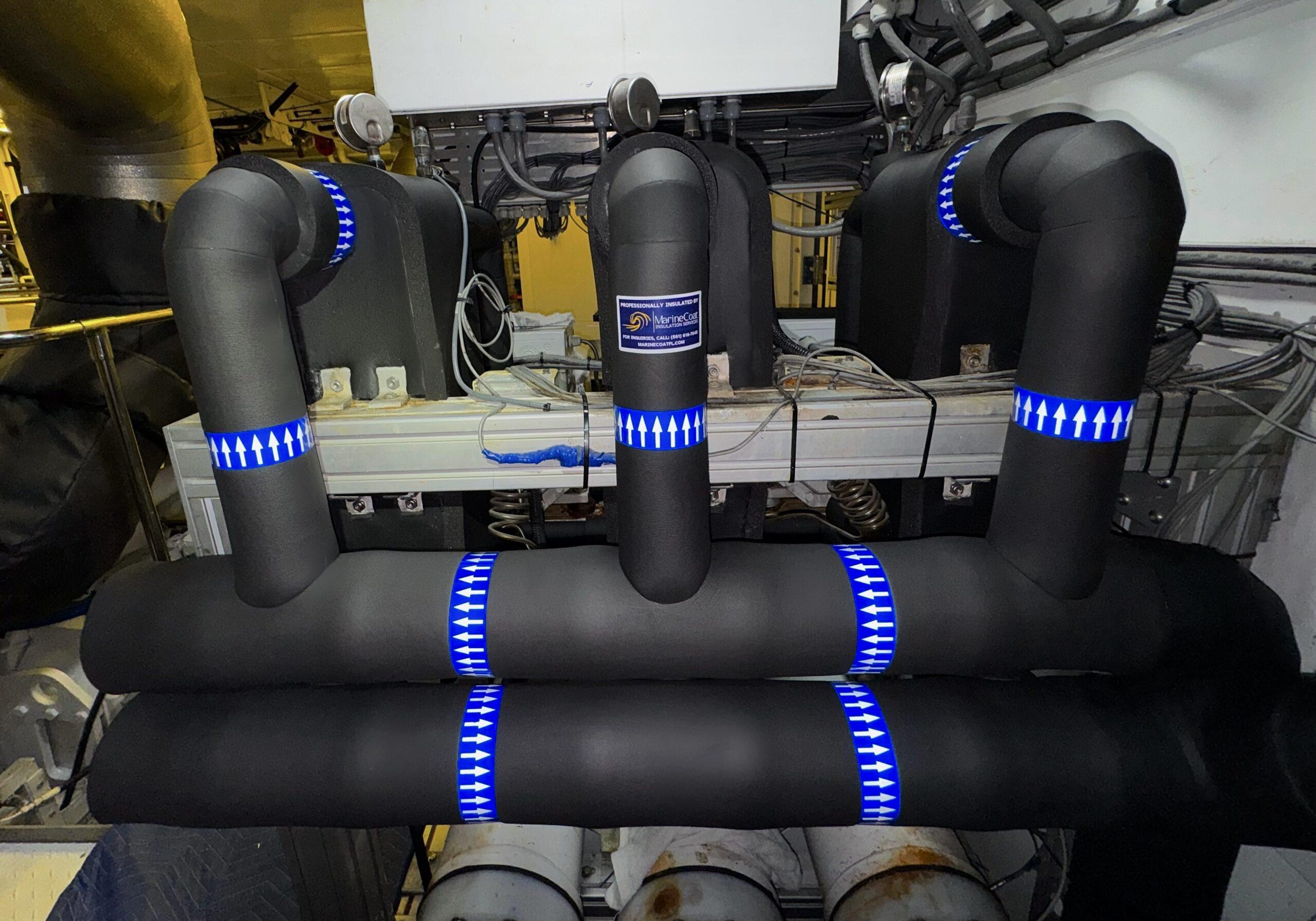

How Marine Insulation Improves Safety in Maritime Operations

Maritime operations involve intricate systems functioning under relentless environmental pressure, where safety is inseparable from technical reliability. From engine rooms to deck-level pipelines, unprotected equipment presents serious hazards related to heat exposure, fire propagation, and structural deterioration. Within the first stages of vessel construction and offshore deployment, marine insulation companies implement protective solutions that minimize operational risk. By applying marine pipe insulation with precision, they help stabilize temperatures, shield crews from accidental contact, and preserve system integrity. Safety in maritime settings depends heavily on insulation strategies designed specifically for seagoing conditions.

Insulation is not merely a supporting element—it is a frontline safeguard that influences every aspect of shipboard safety.

Thermal Control and Crew Protection

High-temperature surfaces pose a constant danger aboard vessels and offshore platforms. Pipes carrying steam, fuel, or exhaust gases can reach levels capable of causing severe injury upon contact.

Marine pipe insulation creates a thermal barrier that lowers external surface temperatures to safe limits. Marine insulation companies engineer these systems to prevent accidental burns while allowing equipment to operate within required thermal ranges. This protective measure significantly reduces workplace injury risk in confined shipboard environments.

Fire Risk Reduction Across Marine Systems

Fire represents one of the most severe threats in maritime operations due to limited evacuation options and proximity to combustible materials. Uninsulated or poorly insulated piping accelerates heat transfer, increasing ignition potential.

Marine insulation companies select fire-resistant materials that delay flame spread and maintain structural stability under extreme heat. Marine pipe insulation acts as a containment layer, slowing thermal escalation and allowing critical response time during emergencies. This fire-mitigating function directly enhances onboard safety outcomes.

Moisture Control and Slip Hazard Prevention

Condensation forms rapidly in marine environments where temperature differentials are frequent. Moisture accumulation on exposed piping leads to dripping surfaces and slippery deck areas.

Marine pipe insulation minimizes condensation by maintaining surface temperatures above dew point thresholds. Marine insulation companies design insulation systems with integrated vapor barriers, reducing water accumulation that could otherwise create hazardous working conditions for crew members.

Structural Integrity and Failure Prevention

Equipment failure often results from prolonged exposure to corrosion, vibration, and thermal stress. These failures can escalate into safety incidents if critical systems malfunction unexpectedly.

Marine insulation companies protect structural components by applying insulation that buffers mechanical stress and environmental exposure. Marine pipe insulation helps maintain uniform temperature distribution, preventing material fatigue that could lead to ruptures, leaks, or sudden system collapse.

Noise Dampening and Operational Awareness

Excessive noise impairs communication and situational awareness aboard vessels. High-decibel environments increase the likelihood of human error during operations.

Marine pipe insulation contributes to acoustic dampening by absorbing vibration and reducing sound transmission. Marine insulation companies incorporate noise-control properties into insulation assemblies, supporting safer working conditions and clearer communication among crew members.

Protection of Hazardous Fluid Transport

Many marine piping systems carry volatile or pressurized substances. Any compromise in containment poses immediate danger to personnel and equipment.

Marine pipe insulation stabilizes internal conditions, reducing pressure fluctuation caused by thermal variation. Marine insulation companies ensure insulation coverage remains continuous around joints and bends, lowering the risk of leaks that could endanger maritime operations.

Compliance With Maritime Safety Regulations

International maritime authorities impose strict safety standards related to surface temperature limits, fire resistance, and insulation performance. Non-compliance can lead to operational delays and safety violations.

Marine insulation companies possess the technical expertise required to meet these regulatory demands. By installing certified marine pipe insulation systems, they help operators maintain compliance while enhancing real-world safety conditions onboard.

Emergency Response Efficiency

During emergencies, clear access to systems and reduced hazard exposure are essential. Insulated components remain cooler and structurally stable, allowing crew members to act without facing immediate thermal danger.

Marine pipe insulation ensures that emergency valves, controls, and pathways remain accessible. Marine insulation companies design insulation layouts that support emergency response protocols without obstructing critical access points.

Longevity and Predictable Performance

Safety deteriorates when systems age unpredictably. Insulation slows deterioration by protecting components from harsh environmental forces.

Marine insulation companies extend the dependable service life of marine infrastructure through carefully applied insulation strategies. Marine pipe insulation maintains performance consistency, reducing unexpected failures that could compromise operational safety.

Risk Mitigation Through Skilled Installation

Even advanced insulation materials fail if installed improperly. Gaps, compression, or unsecured layers introduce vulnerabilities.

Marine insulation companies rely on trained professionals to ensure marine pipe insulation is installed with precision. Proper application guarantees insulation performs its safety function throughout the vessel’s operational lifespan.

Conclusion

Safe maritime operations rely on proactive protection of personnel, systems, and structures. Through thermal control, fire resistance, moisture management, and mechanical shielding, marine insulation companies play a decisive role in reducing operational risk. When marine pipe insulation is applied strategically and accurately, vessels benefit from safer working environments, improved system reliability, and enhanced regulatory compliance across demanding maritime conditions.

- Psychologie und Kommunikation an Bord

- Hafenmanöver

- Segler-Portal

- Versicherungen

- Sicherheit

- Revier- und Reiseberichte

- Organisation

- Yacht

- Technik & Elektrik

- Basiswissen

- Kochen an Bord

- Training

- Tipps und Tricks

- Dit & dat

- Literatur